We recycle cable drums

At Scankab Cables, we do everything to minimize waste and therefore have a focus on recycling.

We prioritize environmentally friendly and safe sorting of waste in our production, and we also use cardboard boxes made of recycled materials.

In addition to this, we use FSC-certified and Nordic Ecolabelled paper, and we make a great effort to recycle our FSC-labeled drums and cable scrap, to make full use of these resources.

Over time, the wooden drums can end up having quite a journey around the world. Here you can see the journey of the drum, from when we deliver it to the customer, until we recycle it and return it to our factory.

"Flatpack"

As part of our drive for sustainability, we have developed a new way of transporting wooden drums back to our factories in Spain.

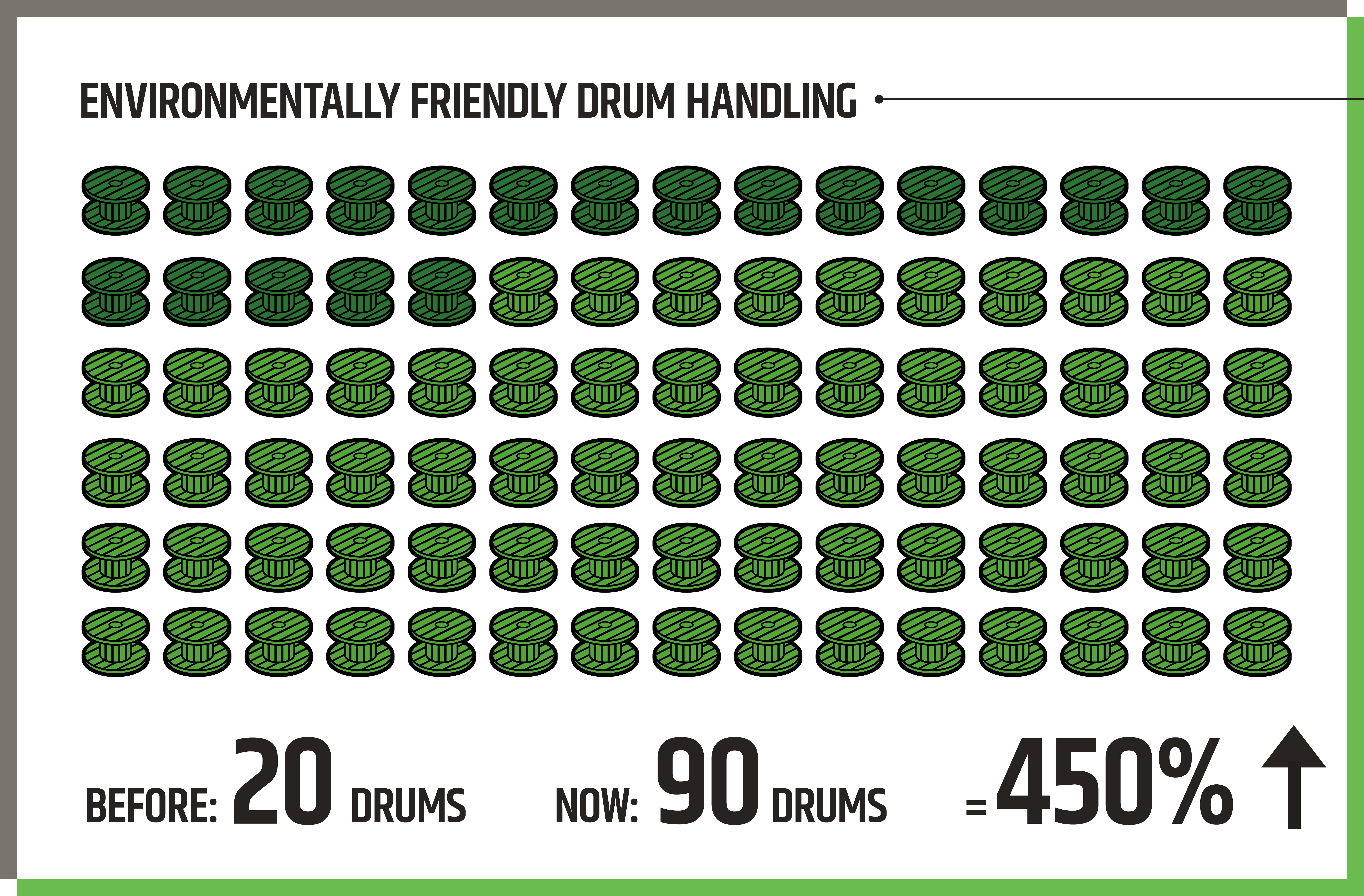

Previously, we would fill a truck with whole drums. Now we have chosen to separate the drums and stack the parts ("flatpack"), so we can transport 90 drums each time, where we could previously only transport 20 drums each time.

So we save approximately 4 trucks each time.

- now that’s what we call environmentally friendly drum handling.

Here you can see the drums that are packed and ready to load into a truck, to be sent to our factories in Spain, where they can be reassembled and reused for new cable.

The truck is filled with 90 drums - as opposed to 20 before.

It's an environmental optimization that can be felt.

Green plastic drums

We use our green plastic drums for our customers in the food and medico industry, and it is not without reason that they are green. The plastic drums are made of recycled plastic from garden furniture, amongst other things, and can be recycled.

"Cut-to-size"

Our cut-to-size setup means that our customers can order cables in measured lengths. In this way, we avoid unnecessary waste and cost. Our production in our own factories allows us to handle extra long lengths on our large recycled clipping drums.