WHEN SERVICE LIFE, PERFORMANCE & TOTAL COST OF OWNERSHIP ARE IMPORTANT

The correct choice of cables will optimise output from the panel array in the short and long term. The cables used must be able to withstand the toughest conditions.

Scankab recommends that installers, consultants and/or the building owner check the cables they normally use an extra time, to ensure they do fulfil the exacting requirements.

HALOGEN-FREE CABLES WITH EXTRA HIGH SAFETY

All our TOPSOLAR H1Z2Z2-K solar panel cables, supplied direct from stock, are made at our own factories, in halogen-free materials, and are approved according to the high Cca CPR class.

Read more about CPR here.

If you are involved in solar panel projects of any size that require solar panel and supply cables, give us a call on +45 7020 3455.

OPTIMISE PANEL ARRAY SERVICE LIFE AND PERFORMANCE

There are many different solar panel cable qualities on the market. Optimise your performance and service life, and the array’s total cost of ownership, by choosing the best. And that’s something Scankab guarantees.

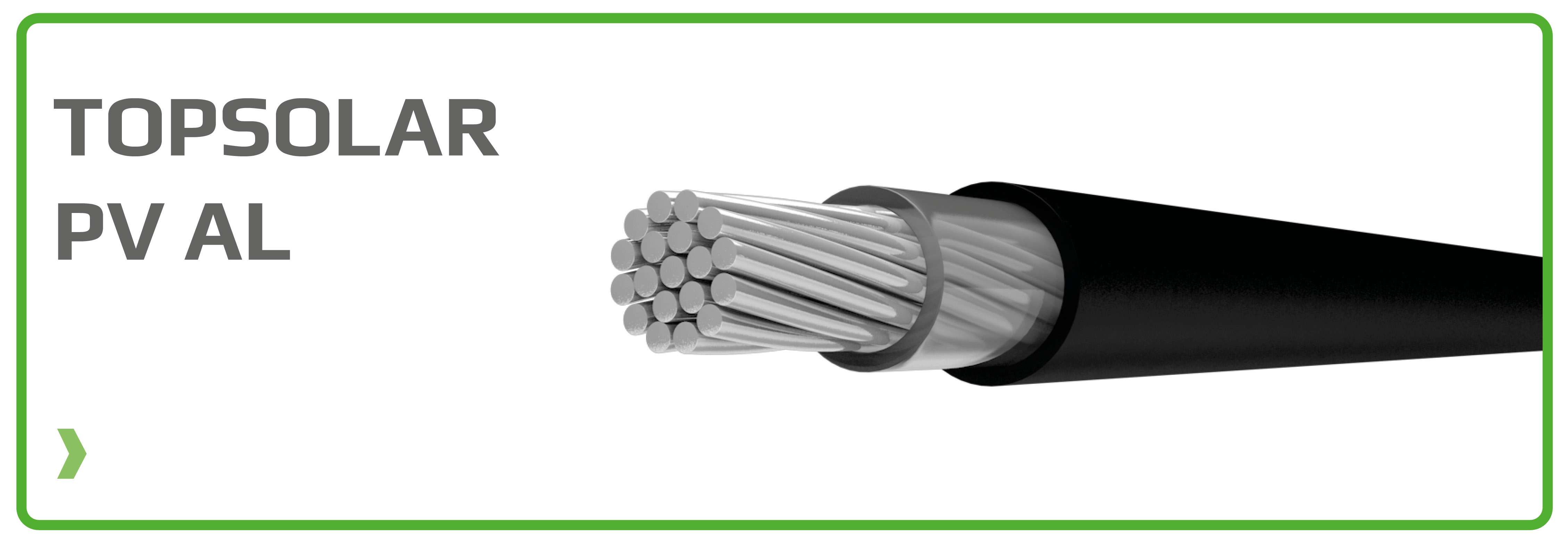

- Halogen-free materials

- Tin-plated and flexible cl. 5 copper wires

- 30-year service life for a 90° C installation

- Approved for rated voltage up to 1,8 kV

- Reduced cable diameter marked in metres

- Produced with TÜV certificate

- Extra high safety level - Cca (EN50575)

- Available in reinforced version

- Supplied on drums or rings, according to customer requirements

PRODUCT FOCUS

RESPONSIBLE FACTORIES

Around 16,000 m² solar cells adorn the roof of our factories in Spain, which means that the factories are 100% self-sufficient with green energy.

The solar cells are of course installed with our own solar cell cables.

Here you can see a small film of the installation on the roof of our factories. Almost 100,000 meters of solar cell cable have been used.

DESIGNED FOR THE TOUGHEST CONDITIONS

Cables used for solar panels differ from cables used in industrial installations, as they have to be designed to withstand tough climate conditions, such as:

- Rain

- UV radiation

- Extreme temperature fluctuations

Cables in a solar panel array typically represent 4-5% of total costs, but can have a significant effect on the final result.

EASY TO HANDLE

Solar panel cables from Scankab feature extremely flexible tin-plated cl. 5 copper wires, and reduced cable diameter to make them easier to handle and install.

WIRE MESH TRAYS FOR SOLAR PANEL ARRAYS

And remember, we stock a complete range of the unique BLACK C8 wire mesh tray system, perfect for solar panel arrays.

BLACK C8 has a higher level of corrosion resistance than traditional hot dip galvanised products on the market.

The black surface gives a more aesthetically-pleasing finish, with black cables, black roof and black solar panels.