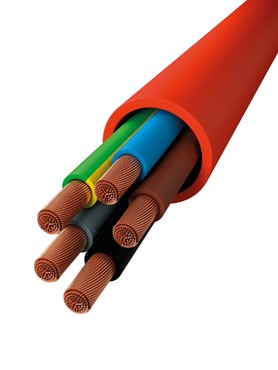

X-PUR ® H07BQ-F - 450/750 V

Application

The X-PUR cable is a flexible and extremely durable cable capable of withstanding strong twists and resisting mechanical stress. The cable can be submerged in fresh or saltwater and is resistant to frost, UV light, impact, and wear. It is designed to endure extreme conditions in various indoor and outdoor environments, making it suitable for numerous applications on land and in water. This includes installations in marine/water environments, aquaculture, mechanical industry, crushing plants, and agriculture.

Construction

Electrolytic annealed Cu, class 5 according to IEC 60228

Thermosetting rubber, type EI6 according to HD 22

According to HD 308 / HD 186

Polyurethan (PUR) compound, type TMPU according to HD 22, meter marked, orange

Technical data

-40° C to +90° C

450/750 V

3 x cable diameter

Short circuit temp.: max 250° C / 5 sec.

Approvals

IEC 60332-1, en 50525-2-21, IEC 60228, HD 22.10 / UNE 21027-10, HAR, AENOR, CE, RoHS| SKU | EAN | Dimension (mm2) | Current Value (A) | Packaging | Diameter (mm)* | Weight (kg/km)* | |

|---|---|---|---|---|---|---|---|

| 6031095001 | 5704403208999 | 1x95 | 328 | D./Cut | 19,6 | 955 | |

| 6031185001 | 5704403209002 | 1x185 | 510 | D./Cut | 26,3 | 1800 | |

| 6031001502 | 5704403209019 | 2x1,5 | 26 | D./Cut | 7,7 | 75 | |

| 6031001503 | 5704403209026 | 3G1,5 | 26 | D./Cut | 8,2 | 95 | |

| 6031002503 | 5704403209033 | 3G2,5 | 36 | D./Cut | 9,5 | 145 | |

| 6031004003 | 5704403209040 | 3G4 | 49 | D./Cut | 13,2 | 245 | |

| 6031001504 | 5704403209057 | 4G1,5 | 23 | D./Cut | 9,1 | 125 | |

| 6031002504 | 5704403209064 | 4G2,5 | 32 | D./Cut | 10,7 | 180 | |

| 6031004004 | 5704403209071 | 4G4 | 42 | D./Cut | 13,2 | 245 | |

| 6031001505 | 5704403209088 | 5G1,5 | 23 | D./Cut | 10,1 | 150 | |

| 6031002505 | 5704403209095 | 5G2,5 | 32 | D./Cut | 12,4 | 210 | |

| 6031004005 | 5704403209101 | 5G4 | 42 | D./Cut | 14,6 | 335 | |

| 6031006005 | 5704403209118 | 5G6 | 54 | D./Cut | 16,2 | 455 | |

| 6031010005 | 5704403209125 | 5G10 | 75 | D./Cut | 21,0 | 770 | |

| 6031016005 | 5704403209132 | 5G16 | 100 | D./Cut | 24,0 | 1105 | |

| 6031025005 | 5704403209149 | 5G25 | 127 | D./Cut | 29,9 | 1705 | |

| 6031035005 | 5704403209156 | 5G35 | 158 | D./Cut | 33,4 | 2260 | |

| 6031050005 | 5704403208975 | 5G50 | 192 | D./Cut | 38,8 | 3125 | |

| 6031001506 | 5704403208982 | 6G1,5 | 23 | D./Cut | 12,9 | 195 | |

| * The values can have small deviations | |||||||